Rice University researchers have developed an enhanced electrochemical reactor that promises a hopeful leap forward in making direct air capture (DAC)—the process of collecting carbon dioxide (CO₂) directly from the atmosphere—more energy efficient. This innovative design has the potential to significantly reduce carbon emissions and promote effective CO₂ mitigation solutions that address pressing environmental issues.

A Breakthrough in Carbon Capture Technology

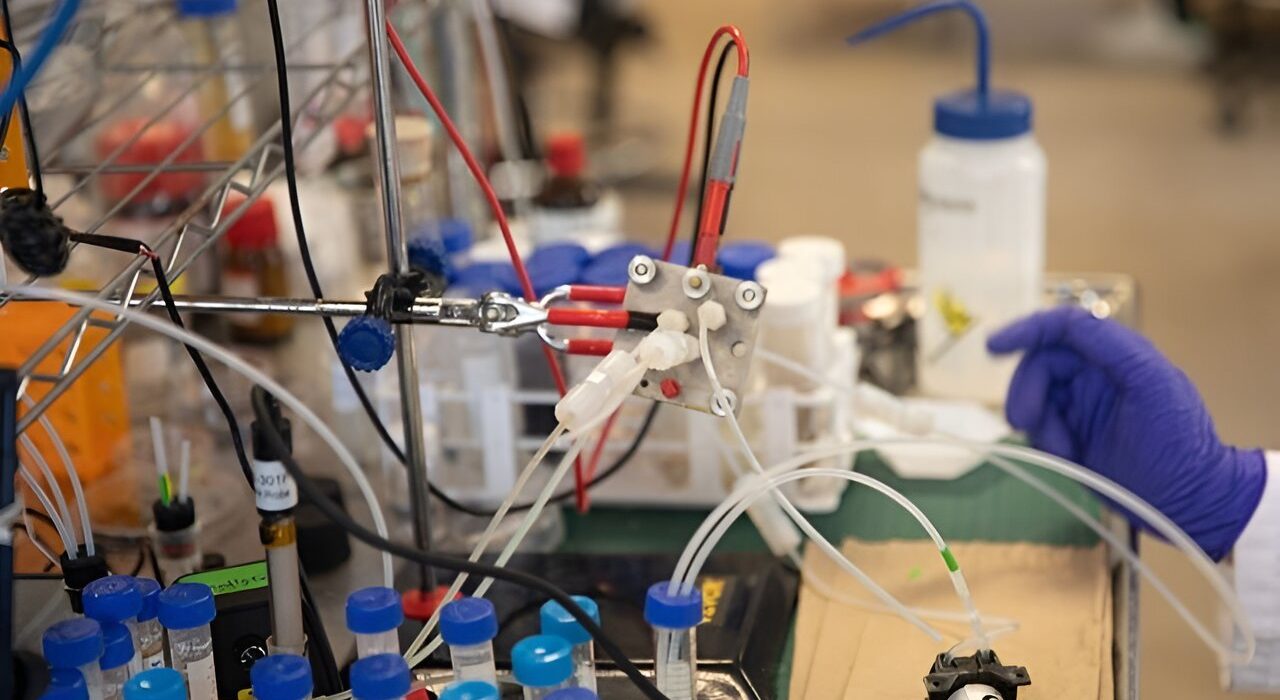

According to a study published in Nature Energy, this new electrochemical reactor has a modular, three-chambered structure with a revolutionary porous solid electrolyte in the center. Haotian Wang, a well-known chemical and biomolecular engineer at Rice, spearheaded this accomplishment. Wang’s lab has been working on sustainable industrial decarbonization and energy solutions. Wang stressed the significance of this research, saying, “Our findings present an opportunity to make carbon capture more cost-effective and viable across industries,” highlighting the reactor’s versatility in a variety of commercial applications.

The reactor’s distinctive structure enables significant rates of CO₂ regeneration from carbon-laden fluids. It has outstanding performance parameters, including long-term stability and flexibility to various chemical reactions, making it ideal for large-scale industrial deployment. One distinguishing feature of the reactor is its flexibility since it can run efficiently with a variety of cathode and anode reactions, potentially serving sectors ranging from energy generation to chemical processing.

Improving Efficiency and Reducing Carbon Capture Costs

The potential to coproduce hydrogen during direct air capture is the most interesting aspect of this novel electrochemical reactor design. According to Wang, this innovation might significantly reduce both capital and operational costs, making net-zero fuel or chemical manufacturing more economically viable. Hydrogen is a vital commodity in a variety of industries, and combining its production with DAC could reduce prices even more, promoting greener fuel alternatives.

This reactor uses electrical energy for regeneration, unlike other DAC techniques that use high-pH liquids or thermal energy to recover CO₂ from air. The electric technique, which operates at room temperature and requires no additional chemical additives, produces fewer undesirable byproducts and more energy-efficient solutions.

Zhiwei Fang, a postdoctoral researcher and co-author of the work, explained that traditional direct air capture technologies use high temperatures to remove CO₂ from sorbent materials. “We used electrical energy, which offers several advantages, including no requirement for heating or additional chemicals.”

The Science of CO₂ Capture and Regeneration

CO₂ capture by DAC generally begins with flowing CO₂-containing air through solutions or materials (sorbents) that bond with CO₂ molecules. Bond strength varies according to the chemical characteristics of the sorbent. To release trapped CO₂ from the sorbent, energy-intensive and costly chemical or thermal reactions are commonly used.

This novel reactor efficiently splits carbonate and bicarbonate solutions, producing an alkaline absorbent in one chamber and high-purity CO₂ in another. This simplifies the process and reduces energy consumption. “Our innovative approach optimizes electrical inputs, which enhances ion movement and mass transfer,” Wang told me. “This process minimizes energy barriers and maximizes efficiency.”

Addressing the Challenges of Conventional Sorbents

Amine-based compounds are commonly utilized as sorbents in DAC due to their ability to create weak connections and facilitate CO₂ release. However, these chemicals are extremely poisonous and environmentally unstable. Water-based sorbents like sodium hydroxide and potassium hydroxide are a more eco-friendly option but require higher temperatures for successful CO₂ removal.

Rice’s reactor uses an electrochemical technique to prevent the use of toxic chemicals and functions efficiently at room temperature, solving some of the major constraints of current DAC technologies. This breakthrough may help overcome the challenges to wider implementation of DAC technologies by making them safer, more sustainable, and cost-effective.

Toward a Net-Zero Future

This revolutionary finding is consistent with Rice University’s strategic focus on sustainable energy solutions. Wang hopes that this reactor, along with other initiatives produced in his lab, will function as a catalyst for industry to embrace more environmentally friendly processes and technology. He continued: “Rice is the place to be if you are passionate about sustainability and energy innovation.”

The project got financial assistance from the Robert A. Welch Foundation and the David and Lucile Packard Foundation, demonstrating notable organizations’ commitment in supporting sustainable innovation.

Looking Ahead: Industry Implications and Broader Applications

This novel electrochemical reactor might have far-reaching effects, opening up new options for industries looking to embrace more environmentally friendly practices. Rice’s reactor, with its versatility to varied chemical reactions and compatibility with multiple sorbents, might easily integrate into existing industrial processes or inspire new green technologies.

Moreover, the collaboration with co-authors, including former Rice postdoctoral researcher Xiao Zhang and alumni Peng Zhu and Yang Xia, emphasizes the teamwork and expertise that went into this success.

At last, Rice University’s electrochemical reactor provides scalable, viable, and energy-efficient ways to reduce atmospheric CO₂, addressing the global climate challenge. With further research and industry partnerships, this innovation has the potential to become a key component of worldwide efforts to achieve net-zero emissions and reduce the environmental effect of industrial activities.