Rice University researchers have developed an innovative way to produce covalent organic frameworks (COFs), a type of crystalline polymer noted for its potential to address crucial environmental concerns. COFs’ porous and adjustable molecular architectures make them suitable for gas trapping, water filtering, and speeding chemical reactions. This revolutionary technology could pave the way for efficient and cost-effective environmental solutions, notably in the decontamination of persistent pollutants such as per- and polyfluoroalkyl substances (PFAS), sometimes known as “forever chemicals.”

PFAS Problem: Why It Matters:

PFAS, a collection of man-made chemicals, utilized in consumer and commercial products for decades. The PFAS, known for its heat, water, and oil resistance, found in nonstick cookware, waterproof fabrics, firefighting foams, and a variety of other products. Unfortunately, PFAS do not degrade quickly in the environment, earning them the name “forever chemicals”. PFAS exposure has linked to a number of health hazards, including cancer, liver damage, and reproductive harm.

Perfluorooctanoic acid (PFOA) is a particularly notorious chemical in the PFAS family, connected to major health problems. Conventional PFAS degradation processes are sluggish and ineffective, necessitating the development of better alternatives. Covalent Organic Frameworks (COFs) have the potential to provide a more sustainable and effective approach to PFAS decontamination.

What are Covalent Organic Frameworks (COFs)?

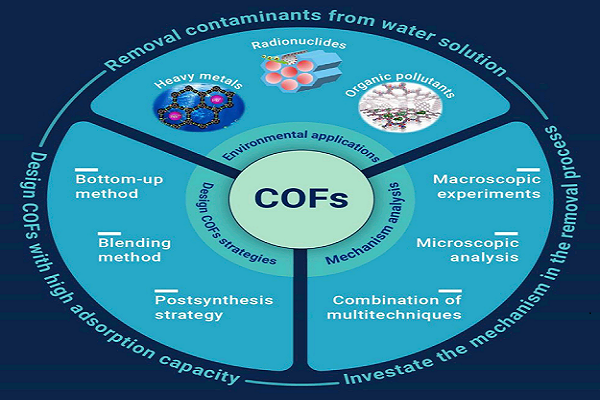

Covalent Organic Frameworks (COFs) are crystalline polymers that comprise small, repeating units that, when viewed under a microscope, resemble sponges. They are distinguished by their huge surface area, high porosity, and adaptable molecular architecture. COFs’ unique features make them highly adaptable and suitable in a variety of sectors, including:

- Gas Capture and Storage

- Water Filtration

- Chemical Reaction Acceleration

- Semiconductors

- Sensors

- Drug Delivery

Despite their enormous promise, COFs have not extensively utilized due to the difficulties connected with production. Traditional COF synthesis processes are costly and time-consuming, frequently requiring the use of hazardous solvents, high temperatures, and high pressures. These restrictions have hampered their widespread use in industrial applications, particularly in environmental cleanup.

Rice University Innovation: A Game-Changing Synthesis Method

Rafael Verduzco, a chemical engineer at Rice University, and his team have devised a new synthesis process for Covalent Organic Frameworks (COFs) that has the potential to revolutionize the area. Verduzco and his colleagues offer a low-cost, high-throughput method for synthesizing COFs utilizing a multiflow microreactor in a paper published in ACS Applied Materials and Interfaces. This approach enables the continuous manufacture of COFs, increasing productivity and quality while lowering prices.

The study presents a small, continuous production system known as a “mini-factory on a lab bench,” in which ingredients are mixed and reacted in a continual stream. This continuous flow technique differs from typical batch synthesis, in which all materials are mixed and reacted simultaneously in a big container. Safiya Khalil, the study’s first author and a Rice University PhD alumnus, described this process as “baking cookies to order in small batches” rather than all at once in a large batch.

Advantages of Multiflow Microreactors

The Rice researchers’ multi-flow microreactor has significant advantages over standard COF production methods:

- Faster Production: The continuous flow technology enables faster synthesis of COFs, lowering the time required to manufacture the materials.

- Lower Energy Consumption: By avoiding the high temperatures and pressures required in classical synthesis, the new approach uses less energy.

- Cost-effective: Lower energy consumption and faster manufacturing cut the cost of COF synthesis significantly.

- Superior Quality: Continuous temperature and mixing control provides for greater control over the end product, resulting in COFs with higher crystallinity and improved performance.

- Environmental Advantages: Traditional processes require harmful organic solvents, but the new technology reduces the need for chemicals, making the process more environmentally benign.

Breaking down PFAS with Covalent Organic Frameworks (COFs)

One of the study’s most interesting results is the freshly synthesized COFs’ ability to degrade PFAS chemicals more efficiently than existing approaches. The Rice team discovered that one of the Covalent Organic Frameworks (COFs) created by their flow synthesis approach was particularly good at breaking down perfluorooctanoic acid (PFOA), a well-known PFAS molecule.

The process by which COFs break down PFOA is known as photocatalytic degradation, and it is triggered by light. Interestingly, this process occurs at room temperature, making it both energy-efficient and applicable to real-world applications. Photocatalysis is a chemical reaction that enhances by the presence of light; in this case, the COFs operate as a photocatalyst, effectively speeding up the breakdown of PFOA into innocuous byproducts.

Photocatalytic Power of Covalent Organic Frameworks (COFs)

Khalil described the COFs as “powerful sponges with built-in ‘ sunlight engines,'” referring to their ability to use light to accelerate the breakdown of hazardous compounds. One of the COFs created by the Rice researchers surpassed titanium dioxide, a typical photocatalyst, in breaking down PFOA. This marks a big step forward in the development of more effective and sustainable pollution control methods.

Titanium dioxide, commonly used in pollution control due to its photocatalytic properties, although its effectiveness in breaking down PFAS is minimal. The better efficacy of the COFs created by Rice researchers could pave the way for more efficient decontamination solutions capable of addressing the global PFAS pollution problem.

Future Applications of Covalent Organic Frameworks (COFs)

Aside from PFAS decontamination, COFs offer a wide range of possible applications in many industries. Their distinct characteristics make them good candidates for usage in

- Energy Storage: COFs help to improve the efficiency of batteries and fuel cells.

- Gas Storage: Due to their huge surface area and porosity, COFs are good at trapping gasses, which could be beneficial in carbon capture methods.

- Drug Delivery: Because of their customizable molecular structure, COFs may deliver medications to specific parts of the body with pinpoint accuracy.

- Sensors: Because of their sensitivity to environmental changes, COFs are suitable in sensors that detect pollution or other dangerous compounds.

Conclusion:

As COF research proceeds, the Rice University team’s unique synthesis approach is likely to serve as the cornerstone for future improvements. Covalent Organic Frameworks (COFs), with their adaptability, hold considerable potential for addressing some of today’s most important environmental concerns, such as pollution control and energy storage. This discovery, which makes COF production more efficient, scalable, and environmentally benign, has the potential to alter industries and lead to new, sustainable solutions for a cleaner planet.